Featured supplier

Lyndex- Nikken

High-Performance Machine Tool Accessories

Lyndex-Nikken`s complete line of high-performance toolholders, presetters, workholding, and machine tool accessories help manufacturers improve their accuracy, efficiency, and productivity. Backed by over a half century of experience, Lyndex-Nikken sets the standard for high quality and innovative tooling and machine tool accessories. Featuring advanced designs and rigid components, our machine tool accessories are built from the ground up for long-lasting precision, reliability, and productivity.

Manufacturers choose Lyndex-Nikken high-performance products for the machining results they get – and that gives them a competitive edge.

- Toolholders and Accessories

- Collets

- Angle Heads and Speeders

- Live and Static Tools

- Presetters

- Workholding

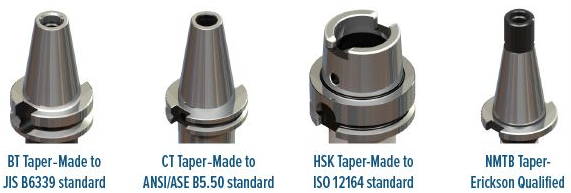

Quality Toolholders with the Nikken Advantage

Quality toolholders produce quality parts that are within the desired specifications. Quality is in the process of manufacturing the toolholder – you’ll never regret choosing quality.

Nikken high quality brand toolholders have been patented in Japan and in many other countries. With unique features, they are used all over the world and have been proving their efficiency for years and years, providing users with benefits that help them stay ahead of their competition:

Sub Zero Treatment

Nikken performs a sub-zero treatment to its tooling. All toolholders are subject to ultra-low temperature treatment of -90° C after carburizing. This treatment removes residual austenite to form 100% martensite compositions to prevent deformation and deterioration over time – this illustrates the quality of Nikken tooling.

Taper Contact

Nikken guarantees 85% of the taper contact ratio. It allows concentricity, run-out accuracy, and stable machining, while also reducing damage to the M/C Spindle and extending tool life. Strong rigidity between machine spindle and toolholder eliminates potential fretting corrosion.

Nikken’s taper characteristics:

- Nickel Chrome 4150 alloy

- AT3 taper or better, 56 to 58 HRc

- Traverse Ground Taper

- Inspected by Prussian Blue oil method

Greater rigidity and higher accuracy allows for more aggressive material removal and part precision. So, Nikken provides the most accurate and precise collet chucks in the industry (guaranteed runout within .0002”). Additionally, Nikken milling chucks are the strongest clamping toolholder in the world with over 3500 ft. lbs of gripping force.

Videos

SK Collet Chucks

Achieve accuracy and precision for optimal machine tool performance due to a titanium nitride (TiN) bearing nut that improves rigidity, narrow body provides better clearance, and taper angle provides increased gripping power. SK collet chucks are ideal for all applications including milling, drilling, reaming, thread milling and tapping.

Watch the video to learn more about SK Collet Chucks.

Multi Lock Milling Chucks

Nikken invented the milling chuck in 1963, and today the Multi Lock Milling Chuck is still the most reliable and powerful toolholder available. Multi Lock milling chucks feature multi-roller bearings and a heavy duty nut for more gripping power. Additionally, spiral coolant slots project coolant at 2 degrees which assures high pressure and volume of cooling during high speed operations. Milling chucks offer a tremendous increase in performance over end mill holders.

VC Collet Chucks

Due to the TiN bearing nut reducing friction, VC collet chucks hold high runout accuracy within 3 microns at 4 times diameter. This produces better stability and improves surface finish and cutting tool life. Ideal for high speed machining, thread milling, and ultra-precision reaming, VC collet chucks are designed with a thick wall design of the holder body that improves cutting rigidity and increases dampening. Additionally, an 8-degree internal taper collet provides greater accuracy and clamping capability – double the gripping power of ER collet chucks.

MMC Mini-Mini Collet Chucks

Featuring a slim and compact body for precision machining with small diameter tools (up to 0.5”), the MMC collet chuck is an ideal toolholder for high-speed, high precision machining applications where clearance is needed such as die mold, aerospace, and medical parts. The MMC is precision ground and pre-balanced to 30,000 RPM at G2.5 runout accuracy of 3 microns at 4 times the diameter. An internal draw-in collet clamping mechanism (no collet nut required) results in strong, high-precision gripping from the front nose.

Watch the video to learn more about MMC Collet Chucks.

Shrink Fit Holders

Extreme gripping and being pre-balanced for up to 25,000 RPM makes shrink fit holders ideal for high-speed applications. Additionally, due to their slim design, shrink fit holders work well for areas where clearance is an issue. Using shrink fit holders will result in excellent surface finish, and will increase cutting tool life, material removal rate, and workpiece accuracy.

Watch the video to learn more about Shrink Fit Holders.

Presetters

Using a presetter enhances accuracy, saves time, ensures consistency, and improves overall machining efficiency. Both mills and lathes throughout the entire machine shop can benefit from the efficiencies gained by using a presetter.

Look for presetters that combine the best of both worlds for thermal stability and optical precision. This combination provides the highest level of repeatability and reproducibility making presetters ideal for most tool measuring and inspecting applications. Elbo Controlli NIKKEN Tool presetters provide this needed precision and are an optimal solution.

Watch the video to find out more about how you can solve your challenges and benefit by using a

presetter